Building the Future of Manufacturing

Trustworthy LLMs and Agentic AI

Executive Summary

Manufacturers today face a dual challenge: trusting AI predictions and acting on them efficiently. Recent research points to a roadmap that strongly aligns with Data Raven’s field experience:

Trustworthy LLMs make predictive analytics auditable and usable on the factory floor.

Agentic AI enables operators to express goals in natural language, with autonomous systems orchestrating the execution.

At Data Raven, we see these approaches validated daily — from electronics production to water-valve manufacturing — where trust and intent-driven orchestration together create measurable efficiency, resilience, and scalability.

Executive Summary

Manufacturers today face a dual challenge: trusting AI predictions and acting on them efficiently. Recent research points to a roadmap that strongly aligns with Data Raven’s field experience:

Trustworthy LLMs make predictive analytics auditable and usable on the factory floor.

Agentic AI enables operators to express goals in natural language, with autonomous systems orchestrating the execution.

At Data Raven, we see these approaches validated daily — from electronics production to water-valve manufacturing — where trust and intent-driven orchestration together create measurable efficiency, resilience, and scalability.

Introduction

Manufacturing is entering a new phase where Industry 4.0’s data-driven optimization must evolve into Industry 5.0’s human-centric orchestration. The challenge is no longer only collecting and analyzing vast amounts of data but ensuring that predictions are trusted and then translated into action.

Two recent research contributions provide complementary insights into this transition:

Pfeiffer et al. (2025) show how trustworthy LLM-driven process intelligence can make predictions explainable and auditable in manufacturing environments.

Romero & Suyama (2025) introduce Agentic AI frameworks that turn operator intents into automated workflows.

Both directions resonate with Data Raven’s implementations in the field, where we consistently see manufacturers demand both transparency and autonomy as prerequisites for AI adoption.

Trustworthy LLMs in Manufacturing

In From Theory to Practice: Real-World Use Cases on Trustworthy LLM-Driven Process Modeling, Prediction and Automation (Pfeiffer et al., 2025), the authors address the core limitation of AI in manufacturing: trust.

Key contributions include:

Predictive monitoring with explainability: By combining process mining, uncertainty-aware machine learning, and explainable AI (XAI), opaque “black-box” predictions become auditable, risk-aware insights.

Conversational process modeling: LLM interfaces democratize BPMN design, enabling engineers and operators to refine workflows without specialized technical training.

Human-in-the-loop collaboration: Rather than replacing experts, these systems enable dialogues between human intuition and machine insights.

This is highly consistent with Data Raven’s manufacturing projects, where factory engineers often reject opaque predictions but quickly adopt AI tools once results are transparent, auditable, and explainable in business terms. For example, in our electronics manufacturing pilots, introducing uncertainty quantification alongside predictions made the difference between operator rejection and enthusiastic adoption.

Agentic AI for Intent-Based Industrial Automation

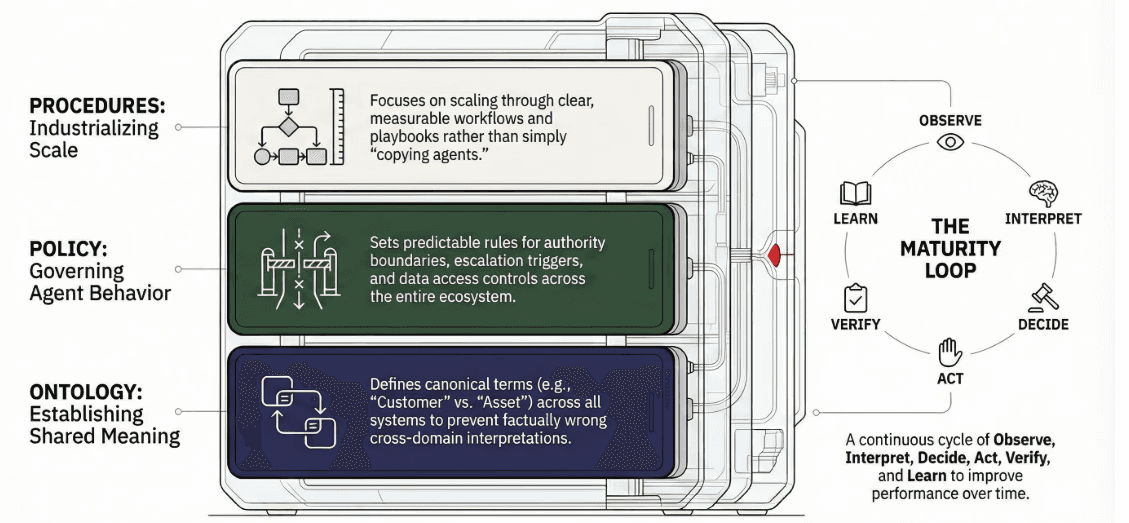

In Agentic AI for Intent-Based Industrial Automation (Romero & Suyama, 2025), the focus shifts from prediction to execution.

Highlights include:

Natural language intent decomposition: Operators specify outcomes (“avoid downtime,” “maximize throughput”), which are translated into structured components for action.

Multi-agent orchestration: A root agent delegates to specialized sub-agents for tasks like predictive maintenance and scheduling.

Proof of concept: Using the CMAPSS dataset, the system produced maintenance plans directly from Remaining Useful Life (RUL) data.

This aligns directly with Data Raven’s field experience: once trustworthy predictive insights are in place, manufacturing clients immediately ask, “Can the system just act on this?” We see growing demand for intent-driven orchestration, particularly in preventive maintenance and adaptive scheduling, where the complexity exceeds what human operators can handle in real time.

Synthesis: From Transparency to Autonomy

Viewed together, the two research streams point to a practical roadmap for manufacturers:

Transparency as foundation: Trustworthy LLMs (Pfeiffer et al., 2025) establish credibility by making predictions auditable and interactive.

Autonomy as the enabler: Agentic AI (Romero & Suyama, 2025) builds on those foundations to execute operator intents via multi-agent orchestration.

Human-centric integration: Both converge on Industry 5.0 principles — augmenting operators rather than replacing them, while embedding sustainability and resilience.

This resonates strongly with Data Raven’s industrial engagements. In practice, we see transparency and trust as adoption gates: manufacturers will not embrace autonomy until they are confident predictions are reliable. Once trust is secured, intent-based orchestration delivers rapid efficiency gains, reducing downtime and unlocking scalable improvements across factories.

Alignment with Data Raven’s Industry Experience

At Data Raven, these findings mirror our hands-on work with manufacturing leaders:

In electronics production, auditable predictive quality control reduced false rejections and built operator trust.

In water-valve manufacturing, intent-based orchestration is now being tested to automate preventive maintenance planning.

In PCB and textile manufacturing contexts, we see the same duality: operators want explainability first, autonomy second.

These real-world projects validate the research consensus: the path to Industry 5.0 is not about replacing human decision-makers, but about building trustworthy predictive systems and then layering agentic orchestration on top.

Conclusion: A Practical Roadmap for Manufacturing

For Data Raven and its clients, the convergence of trustworthy LLMs and Agentic AI suggests a phased strategy:

Phase 1 – Trust-building: Introduce LLM-enhanced monitoring and conversational modeling to deliver transparent predictions.

Phase 2 – Intent-driven orchestration: Use agentic frameworks to allow operators to set goals while agents handle predictive maintenance and scheduling.

Phase 3 – Industry 5.0 integration: Merge transparency and autonomy into human-centric systems that are sustainable, resilient, and scalable.

This roadmap reflects what we already see in our client projects: once operators trust the data, they are eager to let systems take over execution. By moving step by step, manufacturers can avoid “black-box AI” pitfalls while unlocking the full promise of Industry 5.0.

References

Pfeiffer, P., Rombach, A., Majlatow, M., & Mehdiyev, N. (2025). From Theory to Practice: Real-World Use Cases on Trustworthy LLM-Driven Process Modeling, Prediction and Automation. ACM SIGMOD/PODS. arXiv:2506.03801v1

Romero, M. L., & Suyama, R. (2025). Agentic AI for Intent-Based Industrial Automation. Federal University of ABC. arXiv:2506.04980v1

Introduction

Manufacturing is entering a new phase where Industry 4.0’s data-driven optimization must evolve into Industry 5.0’s human-centric orchestration. The challenge is no longer only collecting and analyzing vast amounts of data but ensuring that predictions are trusted and then translated into action.

Two recent research contributions provide complementary insights into this transition:

Pfeiffer et al. (2025) show how trustworthy LLM-driven process intelligence can make predictions explainable and auditable in manufacturing environments.

Romero & Suyama (2025) introduce Agentic AI frameworks that turn operator intents into automated workflows.

Both directions resonate with Data Raven’s implementations in the field, where we consistently see manufacturers demand both transparency and autonomy as prerequisites for AI adoption.

Trustworthy LLMs in Manufacturing

In From Theory to Practice: Real-World Use Cases on Trustworthy LLM-Driven Process Modeling, Prediction and Automation (Pfeiffer et al., 2025), the authors address the core limitation of AI in manufacturing: trust.

Key contributions include:

Predictive monitoring with explainability: By combining process mining, uncertainty-aware machine learning, and explainable AI (XAI), opaque “black-box” predictions become auditable, risk-aware insights.

Conversational process modeling: LLM interfaces democratize BPMN design, enabling engineers and operators to refine workflows without specialized technical training.

Human-in-the-loop collaboration: Rather than replacing experts, these systems enable dialogues between human intuition and machine insights.

This is highly consistent with Data Raven’s manufacturing projects, where factory engineers often reject opaque predictions but quickly adopt AI tools once results are transparent, auditable, and explainable in business terms. For example, in our electronics manufacturing pilots, introducing uncertainty quantification alongside predictions made the difference between operator rejection and enthusiastic adoption.

Agentic AI for Intent-Based Industrial Automation

In Agentic AI for Intent-Based Industrial Automation (Romero & Suyama, 2025), the focus shifts from prediction to execution.

Highlights include:

Natural language intent decomposition: Operators specify outcomes (“avoid downtime,” “maximize throughput”), which are translated into structured components for action.

Multi-agent orchestration: A root agent delegates to specialized sub-agents for tasks like predictive maintenance and scheduling.

Proof of concept: Using the CMAPSS dataset, the system produced maintenance plans directly from Remaining Useful Life (RUL) data.

This aligns directly with Data Raven’s field experience: once trustworthy predictive insights are in place, manufacturing clients immediately ask, “Can the system just act on this?” We see growing demand for intent-driven orchestration, particularly in preventive maintenance and adaptive scheduling, where the complexity exceeds what human operators can handle in real time.

Synthesis: From Transparency to Autonomy

Viewed together, the two research streams point to a practical roadmap for manufacturers:

Transparency as foundation: Trustworthy LLMs (Pfeiffer et al., 2025) establish credibility by making predictions auditable and interactive.

Autonomy as the enabler: Agentic AI (Romero & Suyama, 2025) builds on those foundations to execute operator intents via multi-agent orchestration.

Human-centric integration: Both converge on Industry 5.0 principles — augmenting operators rather than replacing them, while embedding sustainability and resilience.

This resonates strongly with Data Raven’s industrial engagements. In practice, we see transparency and trust as adoption gates: manufacturers will not embrace autonomy until they are confident predictions are reliable. Once trust is secured, intent-based orchestration delivers rapid efficiency gains, reducing downtime and unlocking scalable improvements across factories.

Alignment with Data Raven’s Industry Experience

At Data Raven, these findings mirror our hands-on work with manufacturing leaders:

In electronics production, auditable predictive quality control reduced false rejections and built operator trust.

In water-valve manufacturing, intent-based orchestration is now being tested to automate preventive maintenance planning.

In PCB and textile manufacturing contexts, we see the same duality: operators want explainability first, autonomy second.

These real-world projects validate the research consensus: the path to Industry 5.0 is not about replacing human decision-makers, but about building trustworthy predictive systems and then layering agentic orchestration on top.

Conclusion: A Practical Roadmap for Manufacturing

For Data Raven and its clients, the convergence of trustworthy LLMs and Agentic AI suggests a phased strategy:

Phase 1 – Trust-building: Introduce LLM-enhanced monitoring and conversational modeling to deliver transparent predictions.

Phase 2 – Intent-driven orchestration: Use agentic frameworks to allow operators to set goals while agents handle predictive maintenance and scheduling.

Phase 3 – Industry 5.0 integration: Merge transparency and autonomy into human-centric systems that are sustainable, resilient, and scalable.

This roadmap reflects what we already see in our client projects: once operators trust the data, they are eager to let systems take over execution. By moving step by step, manufacturers can avoid “black-box AI” pitfalls while unlocking the full promise of Industry 5.0.

References

Pfeiffer, P., Rombach, A., Majlatow, M., & Mehdiyev, N. (2025). From Theory to Practice: Real-World Use Cases on Trustworthy LLM-Driven Process Modeling, Prediction and Automation. ACM SIGMOD/PODS. arXiv:2506.03801v1

Romero, M. L., & Suyama, R. (2025). Agentic AI for Intent-Based Industrial Automation. Federal University of ABC. arXiv:2506.04980v1

All rights reserved to Data Raven Technologies